![]()

可调钉子形光斑设计,方便用户通过调整中芯区域和外围区域功率改变输出光斑能量分布形态,可用于低飞溅焊接等应用。

with different output power of the central zone and the surrounding area, which can be applied With adjustable Pin-shape profile design, customer can conveniently adjust the energy profile to the low-spatter welding.

![]()

具备高抗返回光能力,满足有色金属加工等高反光场合的应用需求。

With strong anti-reflection capacity, our laser products can be stably applied in non-ferrous metal processing.

![]()

采用976nm泵浦技术,具有高电光转换效率,有效降低用电成本。

High electro-optical conversion efficiency is offered via 976nm pump technology. The power consumption is reduced.

![]()

采用高可靠产品设计理念,机柜按照IP65防护等级设计。

The product passes several environment tests (temperature cycling test, vibration test, damp heat test, etc.)

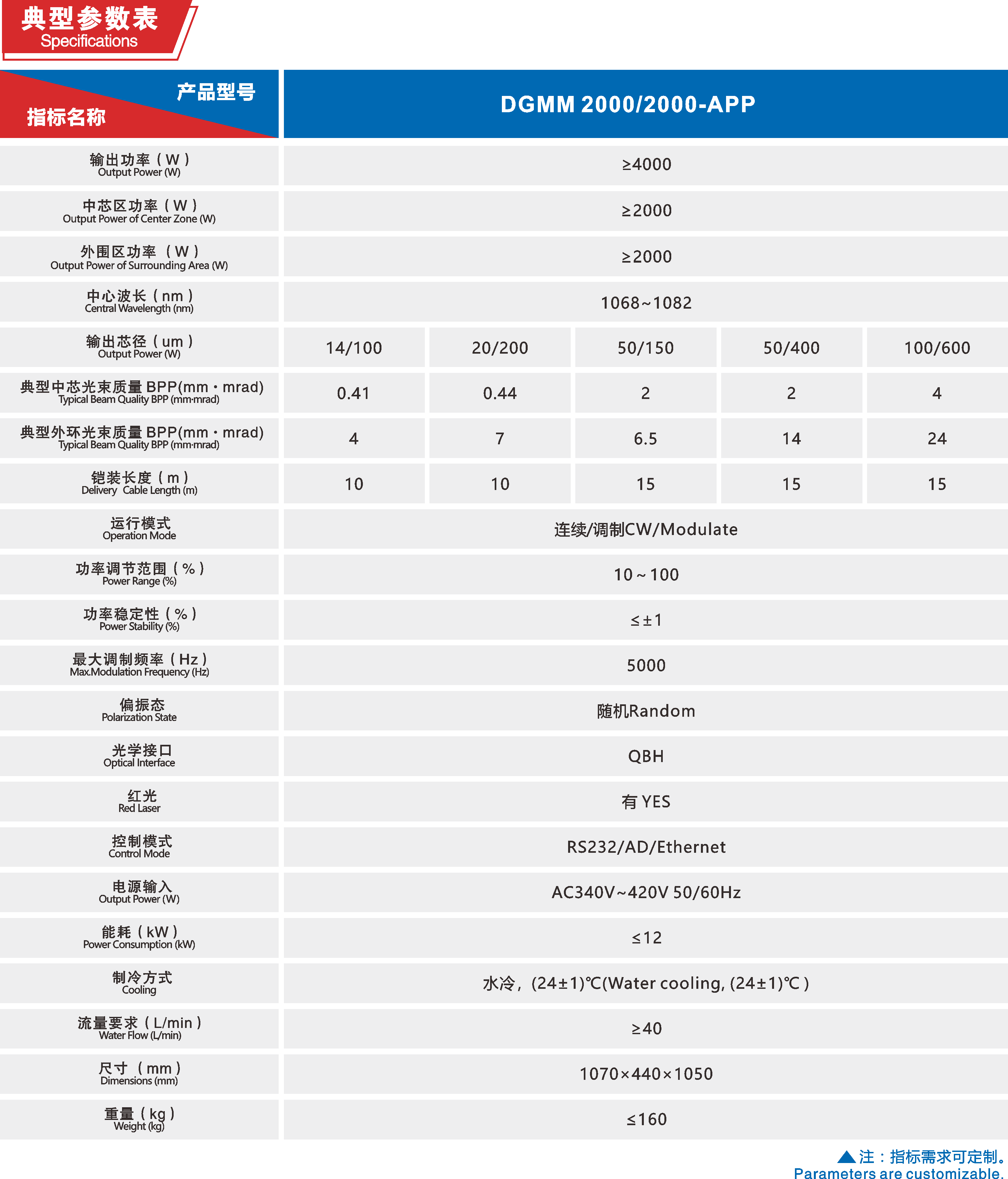

典型参数表 specifications | DGMM 2000/2000-APP | ||||

输出功率(W) Output Power(W) | ≥4000 | ||||

中芯区功率(W) Output Power of Center zone(W) | ≥2000 | ||||

外环区功率(W) Output Power of Surrouding area(W) | ≥2000 | ||||

输出芯径(μm) Output Fiber Diameter(μm) | 14/100 | 20/200 | 50/150 | 50/400 | 100/600 |

中心波长(nm) Central wavelength(nm) | 1068~1082 | ||||

运行模式 Opration Mode | 连续/调制CW/Modulate | ||||

典型中芯光束质量BPP(mm·mard) Typical Beam Quality BPP(mm·mard) | 0.41 | 0.44 | 2 | 2 | 4 |

典型外环光束质量BPP(mm·mard) Typical Beam Quality BPP(mm·mard) | 4 | 7 | 6.5 | 14 | 24 |

铠装长度(m) Delivery Cable Length(m) | 10 | 10 | 15 | 15 | 15 |

功率调节范围(%) Power Range(%) | 10~100 | ||||

功率稳定性(%) Power Stability(%) | <±1 | ||||

******调制频率(Hz) Max.Modulation Frequency(Hz) | 5000 | ||||

偏振态 Polarization State | 随机Random | ||||

光学接口 Optical Interface | QBH | ||||

红光 Red Laser | 有 YES | ||||

控制模式 Control Mode | RS232/AD/Ethernet | ||||

电源输入 Power Supply | AC340V~420V 50/60Hz | ||||

能耗(kW) Power Consumption(kW) | ≤12 | ||||

制冷方式 Cooling | 水冷,水温(24±1)℃ Water Cooling, (24±1)℃ | ||||

流量要求(L/min) Water Flow (L/min) | ≥40 | ||||

尺寸(mm) Dimensions(mm) | 1070×440×1050 | ||||

重量(kg) Weight(kg) | ≤160 | ||||

注:指标需求可定制。Parameters are customizable.